Building

a 2-element Tape Measure

Yagi

During

the March 22, 2018 meeting, Dave Joseph W1AMX discussed how to

construct a simple 2-element direction-finding yagi for 2 meters. The

antenna can be made with about $12 in materials, all of which are

readily sourced at the local hardware store, and common

hand tools.

Parts List

- 9 ½

inches of ½

inch schedule 40 PVC pipe

- 1-½

inch schedule 40 cross connector

- 1-½

inch schedule 40 T-connector

- 1-½

inch schedule 50 cap

- 1

inexpensive tape measure (a 1 inch wide tape is recommended)

- 4

feet of coax cable with a connector on one end (UHF, BNC, SMA, etc.)

and the other end prepared for soldering

- 4

#12 (11/16 inch to 1 1/4 inch) hose clamps

- 5

inch piece of solid wire for hairpin tuning component (14 to

18 gauge will work)

Tools

required

- Hacksaw

or PVC pipe cutter

- Soldering

iron or gun

- PVC

cement

- Electronic

solder

- Wire

cutter

- Hot

glue gun

- Tape

measure

- Tin

snips

- Black

indelible marker

- Metal

file

- Flat

blade screw driver or 5/16 inch nut driver (to tighten hose clamps)

Step

1

Cut a

3 inch length of PVC pipe, and another that's 6 1/2 inches. The

3" length will be used to form the boom between the director and driven

element, and the 6 1/2" pipe will be used to form the handle, so you

can hold the antenna from the rear. Optionally, you may use an elbow to

angle the handle downward, but this depends on preference. Before

cutting the

pipe, measure and mark the length using a black indelible

marker.

Step

2

Cut

two lengths of tape measure to 18 5/8", which will be used for the

driven element, and another length of tape measure to 37 3/16", which

will be used for the director. Once cut, round off the corners of the

outside edges of the tape measure elements and cover them with

electrical tape, for safety. Then, sand and tin the other ends of the

driven elements, so it will make good electrical contact with the

feedline.

Step

3

The

time to tin the driven elements is BEFORE you connect them to the PVC

pipe, so the extra heat required to do so won't melt the plastic

pipe. Next, form the 5" wire into a "U" shape, with the two

legs

about 3/4" apart. Tin the ends of the hairpin to make it easier for

soldering later.

Step

4

At

this time you can pre-assemble the PVC boom, connecting the cross and

T, which will support the tape elements. PVC glue is not required,

since the pipe will press in securely to the fittings, but you can use

it if you choose to. When assembled, the cross and T will be 4 inches

center to center.

Step

5

Finally, use the stainless steel hose clamps to secure the tape measure

elements to PVC fittings as shown in the diagram.

More information about this, and other RDF

projects can be found at the

links below:

Dave

W1AMX also calculated measurements for the same antenna, but for use on

440 MHz. See below:

441

MHz 2 Element Yagi

Numbers are rounded off for ease in measurement.

No hairpin match needed.

Driven: 2 X @ 6.5"

Director: 11.70"

Spacing: 3.3"

Forward Gain: 3.78 dBd (7.112 X input power)

Front to Back: 8.52 dB

Calculated SWR @ 441 MHz: 1.07:1

1.5:1 VSWR Bandwidth: 20.053 MHz.

2.0:1 VSWR Bandwidth: 39.411 MHz.

Be sure to keep the spacing between the driven elements to about

1/4"-3/8".

HT

Tricks for Radio Direction

Finding

Use 'Body Shield/Fade' to get fade on

signal. Direction to

travel will be behind you.

When the null gets shallow..use one, some or all of the following with

'Body Shield/Fade' technique...

- Rotate radio 90 degrees for ~20 dB attenuation.

- Slip tin foil 'glove' over antenna.

- Radio in VFO mode - tune 5 kHz off frequency.

- Use paper clip for antenna.

If direction suddenly changes bearing - you've been following a

reflection.

Try to stay away from metallic objects (fences/buildings etc.)

If

no null disconnect antenna and look for signal using body. If

signal found - you may have 'arrived'. Start looking around.

Easy Loop Design

Here's

an easy method to make a loop for any frequency, courtesey of Dave

Joseph W1AMX. You'll need some 75-ohm coax to make a

transformer

to match to 50 ohms.

VHF Loop (146 MHz)

Length of wire/tubing = 1005/146=82.603"

Loop diameter will be: 26.31" - or -

A square with 20.65" sides. Feed square at one corner.

Use

RG-59 cable for matching transformer. Length will be the same

as one

side of loop (or 1/4 the total length of wire/tubing), minus the

velocity factor. i.e. 20.65" X .66 (velocity factor) = 13.63"

-

that's the length of your 75-ohm cable.

Use your favorite connector at end of 75-ohm cable to connect a 50 ohm

jumper to the radio. (BNC, UHF, etc.)

UHF Loop (445 MHz)

Length of wire/tubing = 1005/445=27.1"

Loop diameter will be: 8.63" - or -

A square with 6.775" per sides. Feed square at one corner.

Use

RG-59 cable for matching transformer. Length will be the same as one

side of loop (or 1/4 the total length of wire/tubing), minus the

velocity factor. i.e. 27.1"/4 = 6.775" X .66 (v/f example) =

4.472" -

that's the length of your 75-ohm cable. |

|

Use

your favorite connector at end of 75-ohm cable to connect a 50 ohm

jumper to the radio. (BNC, UHF, etc.)

With

either loop design, an insulated square/rectangle with screws to mount

loop ends and holes to ty-wrap the coax to works well. Then some kind

of handle to that.

Use 1005/F(MHz) plus 1/4 of that for 75 ohm matching cable (+velocity

factor reduction) for any frequency you want.

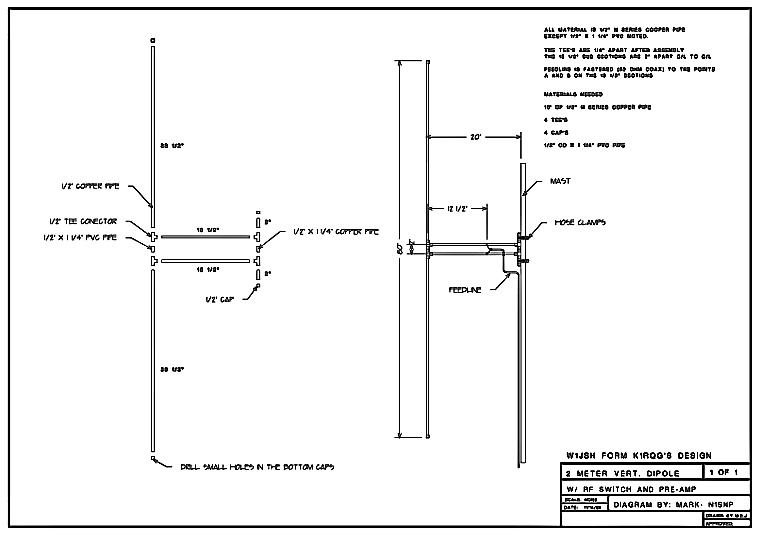

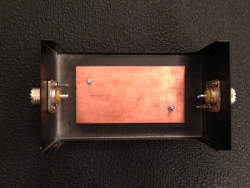

Building

a 2 meter Copper Dipole

Recently, we built one of the

K1RQG-designed 2m copper dipoles, and

construction is quite simple. All that's required is some 1/2" M Series

copper pipe, a small piece of PVC, some tees and end caps, and a

chassis-mount PL259 connector (to connect the coax). Its possible to

omit this and solder a split piece of coax directly to the antenna, but

for durability purposes, its recommended to use the

connector.

All material is 1/2" M Series copper pipe, except 1/2" X 1 1/4" PVC

(noted).

The tees are 1/4" apart after assembly.

The 18 1/2" subsections are 2" apart C/L to C/L.

Feedline is fastened (52 ohm coax) to the points A and B on the 18

1/2"sections.

Materials

needed:

10' of 1/2" M Series copper pipe

4 tees

4 caps

1/2" OD X 1 1/4" PVC pipe

After

cutting the pipe to the lengths shown in the diagram, lay it out

on a large, flat surface, and fit it together. Its recommended,

however, to leave some extra length on the 38 1/2" sections

(the

two longest sections), in case the material is needed during tuning.

Once everything fits up nice, sand both ends of each joint with either

a 3M pad or fine grit sandpaper to prep it for soldering.

When

you're satisfided with the fitment, sweat the joints, and don't forget

to put the PVC spacer in place before soldering. Once this is complete,

attach the PL259 connector, as shown (above right). Now its time to

attach some coax and hook it up to an analyzer for final tuning. If

trimming is required, make the cuts as needed and solder on the end

caps. Finally, mount it up on a mast and begin transmitting.

Click

here to download a high

quality PDF of the diagram shown above.

Installing

Optional Filters in

the Yaesu FT 857

Recently I decided to upgrade my Yaesu FT

857d field radio with

accessory filters (available through W4RT Electronics).

The ones I opted for are the 300-Hz (for CW) and 2.3-kHz (for

ssb)

Rockwell Collins mechanical filters. Installation is relatively easy,

but there are a few things to look out for.

The first step is

to disconnect any power source, and then to remove any mobile brackets

(if used). Next, we'll remove the 7 screws that attach the top cover (4

on the sides and 3 on top). Be sure not to unscrew the speaker screws,

as this is unnecessary. Once the screws are out, the top cover

slides off in the direction of the faceplate. The first thing

to

be careful of is not to damage the speaker wire, which will still be

connected. This wire can be detached from the board, but it

should be long enough to be able to set the cover on its side

and

out of the way.

The

filters plug into the front right of the main board (if looking at it

from the control head). The spaces on the board are labeled FIL1 and

FIL2 respectively, allowing up to two filters to be installed at any

given time.

If you look closely at the filter slot, you'll

notice that on one side (LHS) there are 3 pins, and on the other side

(RHS), there are 4. When the filter is oriented properly, these should

line up perfectly with the female receptacles on the filter. Simply

align the filter (writing side up), and press into place. Press it

gently, however, to be sure not to bend any of the pins.

At this

point, your work is almost done. Slide the cover back in place, secure

it with the 7 screws, and reconnect to a power source. There's one more

step involved to begin using your filters. Press the B button (in Multi

Function Row 'n') to activate the optional filter installed in FIL1 (in

my case this was the ssb filter), and Press C to activate the filter

installed in FIL2. In some cases, you may have to change the setting in

Menu Mode No-086 to "FIL1" or "FIL2" as well to activate one or the

other.

After doing some preliminary tests, I'm astounded by

the performance of these. The CW filter, especially, makes a huge

difference. It has excellent frequency response, with very sharp

skirts, and no noticeable distortion.

CW

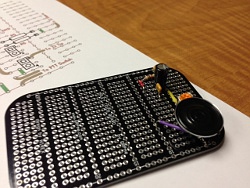

With Your HT

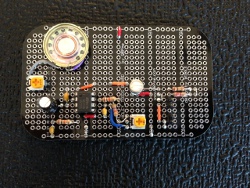

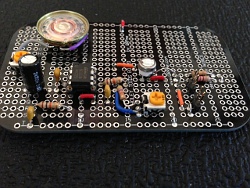

Our CW With Your HT project is to

build a simple

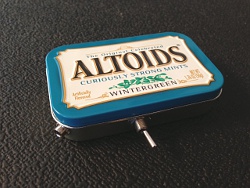

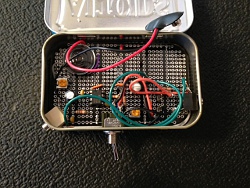

device

that can be used with any handheld tranceiver to send modulated CW. It

is basically an audio oscillator and keying circuit which acts as an

interface between a cw key and a handheld radio. Modulated CW is

nothing more than audio tones keyed on and off and fed to your

transceiver's audio jack. The circuit design, including speaker and 9V

battery are small enough to fit inside an Altoids tin, or similar

enclosure, so it can easily fit in your pocket or be stowed with your

HT. Please find the schematics below, (drawn by Roger Pience, N1XP), as

well as a detailed parts list. As we build these over the next several

weeks, we'll post images of the construction process.

Parts

List

R1,

R2

R3

R4

R5

R6

R7

R8

C1, C2

C3

C4

U1

J1

J2

SPK-1

S1 |

10k0

/

1/4W Resistor (10,000 Ohms, Brown, Black, Orange)

47k0 / 1/4W Resistor (47,000 Ohms, Yellow, Violet, Orange)

100k Potentiometer (100,000 Ohms, Marked 104)

100k / 1/4W Resistor (100,000 Ohms, Brown, Black, Yellow)

2k2 / 1/4W Resistor (2,200 Ohms, Red, Red, Red)

1k0 Potentiometer (1,000 Ohms, Marked 102)

5k0 Potentiometer (5,000 Ohms, Marked 502)

0.01 uF / 50V Capacitor (Marked 103)

220 uF / 16V Electrolytic Capacitor

0.1 uF / 50V Capacitor (Marked 104)

NE-555 Integrated Circuit

3.5mm phone jack, mono

3.5mm phone jack, stereo

Speaker, 7 Ohm, 22mm-round

Switch SPST |

Additional Parts:

Bread Board or Holey-Toids Board (available at QRPme.com)

Enclosure

Battery Leads

8-pin IC Socket

Reference:

Circuit

Diagram (Image)

Carbon Composition Trimmer Potentiometers

Aluminum Electrolytic Capacitors |

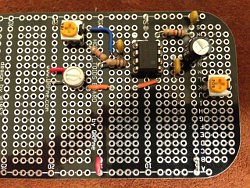

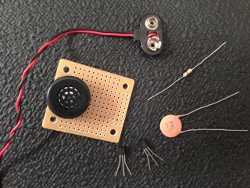

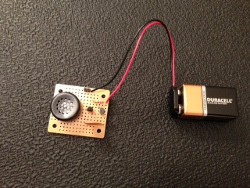

Building

a Miniature Code

Practice Oscillator

At

November's club meeting, Roger Pience N1XP, supplied kits of his own

design, and helped members build miniature code practice oscillators.

The kits are relatively easy to build and only require a battery

connector, 100k resistor, .50 uF capacitor, a couple of transistors,

and a small solderable bread board. It's also recommended that you

include a couple of leads or posts to attach a straight key.

Parts List

- 9V

Battery Connector

- 100k

Resistor

- .50 uF

capacitor

- 3904

Transistor

- 3906

Transistor

- Bread

Board

If

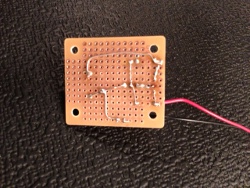

you look at the picture of the underside of the board, you'll see that

we also added some wire to complete the circuit, however most of the

contacts can be made by using the leads of the individual components,

bent over and soldered in the appropriate place. The best way to start

is by positioning a few components on the board, pushing their leads

through, and soldering them to the board, leaving their leads long. As

you add components, simply fold the leads over the back side and begin

to form the circuit, then do a final solder, adding wire where

necessary, and trim the excess material. After you complete this, plug

in a battery and a key, and you'll be making sound!

If you're interested in a kit,

complete with all the parts necessary,

please contact Roger Pience at: xp@n1xp.com

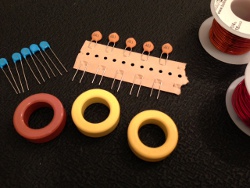

A

Band-Pass Filter for Field

Day

Field Day, for multiple transmitter

categories, presents interference

problems not normally associated with single-station setups. Unwanted

harmonics and receiver blockage are not only a nuissance, but can

potentially cause damage to your receiver as well. The solution are

these relatively inexpensive band-pass filters, which provide for

higher-power handling, increased reliability and

greater frequency attenuation than other designs. Our filters

are based on the Chebyshev 3-resonator design, as presented by Ed

Wetherhold, W3NQN in the 1998 QST article, Clean Up Your

Signals with Band-Pass Filters.

The

performance of these filters is obtained by employing the

three-resonator configuration,

using inductors wound on powdered-iron or phenolic torroidal cores, and

series-parallel connected, high-voltage, low loss NP0 ceramic

capacitors. If you're a contester, especially one who's involved in

multi-transmitter activities such as Field Day, these filters are what

you need!

The materials you'll need to get started

are enclosures (we recommend

ones sized 5 1/4" X 3" X 2"), torroidal cores (T-130-17, T-130-6,

T-130-0, T106-0), copper-clad laminated sheets, ceramic disc capacitors

(15pF/4KV 10%, 110pF/2KV 10%, 30pF/3KV 10%, 220pF/1KV 5%), 18g, 16g,

and 15g magnet wire (for winding) and PL259

chassis connectors. For a complete list, as well as detailed

instructions, please refer to the following articles:

Clean Up Your Signals With Band Pass Filters

Clean Up Your Signals With Band Pass Filters

(Part 2)

(Assembly process shown) - Note that the

copper-clad sheet is riveted

to the floor of the enclosure, and PL-259 connectors are mounted.

Next, a piece of braid or wire is used to ground the chassis

connector to the copper sheet, then the wound torroid is soldered,

along with appropriate capacitors, to create a 50W tap. The core bodies

are attached to the copper sheet with hot glue to prevent

wire-to-ground contact.

Our

filters were modified, assembled, and tuned by Roger Pience, N1XP.

Note, that since we use a slightly larger enclosure than the one

recommended in the original QST article, the torroidal cores can be

arranged in an orderly fashion with less chance of passband loss caused

by the proximity of the other cores or the enclosure.

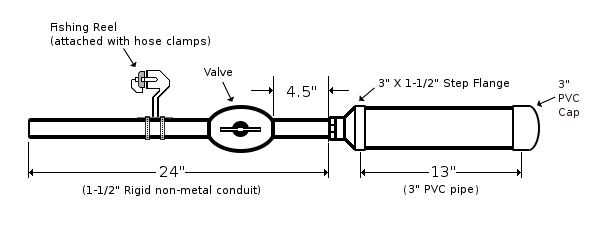

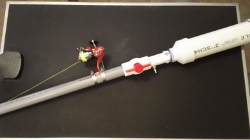

Building

a Pneumatic Antenna

Launcher

In

the Summer of 2012, WSSM members built pneumatic antenna launchers,

under the direction of Steve Freeman K1MV, who built the original

prototype. The launchers are constructed using 3" and 1-1/2" pvc

piping, and air gage, schrader valve, and a fishing reel. With about 40

pounds of air, they are capable of launching a weighted plastic slug

several hundred feet - perfect for putting up that next wire antenna!

Parts List

- 3" PVC

pipe X 13" long

- 3" PVC

pipe dome cap

- Step

flange (3" down to 1 1/2" pipe)

- Total

of 24" long X 1 1/2" rigid non-metal conduit

- valve

for 1 1/2" pipe

- Fishing

reel

- 2 hose

clamps

- 1

Schrader valve

- 6" of

3/4" PVC pipe (to be cut in half for slugs)

- 4

3/4" dome caps (for slugs)

- Eyelet

(for attaching fishing line to slug)

- Fly

line

Tools

required

- Hacksaw

- PVC

cement

- Tape

measure

- Black

indelible marker

- Metal

file

- Electric

drill

- Flat

blade screw driver or 5/16 inch nut driver (to tighten hose clamps)

Begin

by cutting your pipe to the sizes shown below, then file

rough

edges and prefit. The open/close valve should be located about 4 - 1/2"

from the air chamber. Be sure to prep the areas to be glued, and allow

adequate drying time before applying any air pressure. I mounted the

shrader valve in the small pipe section, between the open/close valve

and the flange, and the pressure gage (optional) was mounted on the air

chamber section itself. Its a good idea to add a pressure gage, unless

you have an accurate one on your compressor or air tank, because this

is what determines distance when firing the slug. It is not necessary

or recommended that you fill it with any more than 40 pounds.

Mounting

the fishing reel is relatively simple. Any open reel will do, and its

personal preference whether to mount it on the top or bottom of the

pipe. As far as the slug goes, its just 3/4" PVC pipe, cut to about 6"

long and capped on both ends. Before assembling it, cut a small piece

of scrap wood for the inside for the eyelet to screw onto, and its a

good idea to fill the slug with sand so that it has enough weigh to

drop down the other side of that tree you'll be firing at. Another good

practice is to either paint it a bright or flourescent color, or wrap

it in a bright tape to make it easier to locate.

Firing

the antenna launcher is pretty easy, but it takes a steady hand. Once

air is pumped into the chamber, be sure not to point it at yourself or

anyone else as the projectile comes out very quickly. Its also a good

idea to wear safety glasses. The idea is to point it just slightly

above the tree that you're aiming at and quickly open the valve, to

release all the air in the chamber at once.

Building

a 3-element Tape Measure

Yagi

In

the September / October 2011 newsletter we discussed how to construct a

transmitter that can be used for radio direction-finding. But

there is another piece of equipment you'll need to consider before

heading out to the field for a transmitter hunt - an antenna! For

reasons of simplicity, and because they are relatively inexpensive to

make, we chose to build a "tape measure" antenna. Below, you'll find

directions on how to build your own 2 meter direction-finding antenna.

Parts List

- 3

feet of ½ inch schedule 40 PVC pipe

- 2-½

inch schedule 40 cross connectors

- 1-½

inch schedule 40 T-connector

- 1-½

inch schedule 50 caps

- 1

inexpensive tape measure (a 1 inch wide tape is recommended)

- 4

feet of coax cable with a connector on one end (UHF, BNC, SMA, etc.)

and the other end prepared for soldering

- 6

#12 (11/16 inch to 1 1/4 inch) hose clamps

- 5

inch piece of solid wire for hairpin tuning component (12 to

18 gauge will work)

Tools

required

- Hacksaw

or PVC pipe cutter

- Soldering

iron or gun

- PVC

cement

- Electronic

solder

- Wire

cutter

- Hot

glue gun

- Tape

measure

- Tin

snips

- Black

indelible marker

- Metal

file

- Flat

blade screw driver or 5/16 inch nut driver (to tighten hose clamps)

Step

1

Cut

an 11 ½ inch, and two 7 inch pieces of PVC pipe. Before cutting the

pipe, measure and mark the length using a black indelible

marker.

Step

2

Assemble

the cut lengths of pipe as seen in the drawings to create the boom of

the antenna. Begin by connecting a T-connector to

one end of your 11

1/2 inch pipe, and a cross connector to the other. Then add one of the

7 inch pipes to the cross connector. Glue the remaining cross connector

to the end of this pipe and connect the last pipe to this cross

connector. Make sure that you align the cross connectors. The easiest

way to do this is to place them on a flat surface and twist them to be

flat with the surface. Finish this step by adding the cap to the open

end of the last pipe.

Step 3

Cut four pieces

from the inexpensive tape measure: 41 3/8 inch, 35 1/8 inch, and two

lengths of 17 3/4 inches. Be careful not to cut yourself on the sharp

corners or ends. Use your tin snips to carefully round off the sharp

edges.

Step 4

Now

attach the longest (41 3/8 inch)

piece of tape to the cross connector closest to the end with the cap.

It will be helpful to mark the center point (20 11/16 inches) with your

black indelible marker. Position the tape over the cross connector, so

the curve

of the tape is similar to the curve on the cross connector. Center and

secure the element with hose clamps on each side. Next,

attach the next longer element (35 1/8 inch) to the T-connector at the

opposite end of the boom in a similar fashion.

Step

5

The

next step is to take the 5 inch piece of wire and bend it into a "U"

shape about 3/4 inch wide. Then tin the ends of the wire. This will be

used to make the “hairpin match.” Scrape or file about 1/4 inch of

paint

off the back side of one of the ends of the two remaining pieces of

tape. Tin the bare areas, then attach the hairpin match and coax wire

with solder as shown in the diagram.

Step 6

Next

attach this assembly to the boom using the two remaining hose clamps.

The soldered joints are then covered with hot glue to seal and help

waterproof it. For a balun, 4 or 5 turns of the coax feed

wound round

the boom should do the trick. Now your antenna is ready for use.

For more information on tape

measure yagis, check out the following

links:

Building

a Direction-Finding

Transmitter

One of the most enjoyable projects that we

tackled this summer was

constructing a pair of transmitters for radio direction-finding. Of the

two that we

built, one is a modulated-CW beacon, like the ones used for

International ARDF competitions, and the other is a "voice" beacon.

While researching for this project, we discovered Bob Simmons' (WB6EYV)

boards that could be used in their construction. We chose the MicroHunt

and SqwakBox transmitters.

The

MicroHunt transmitter produces about 50 milliwatts of FM-modulated CW

on 2-meters on a board measuring 0.9 X 1.2 inches. It comes partially

assembled, and the PIC micro (that generates the CW message an ID at

regular crystal-controlled intervals) can be pre-programmed before

shipping. What we find upon delivery is a tiny board with mounting

points for power and an antenna.

The

MicroHunt is intended for competitive transmitter hunts, where multiple

transmitters operate sequentially on a single channel. For this reason,

crystal timing is essential to prevent transmission overlaps. It can

also be used as a DF "homing beacon" on free-flight balloons. It uses a

PIC 12F675 micro for supervision as well as a strap programmable,

crystal-controlled PLL synthesizer chip. Ground range, depending on

antenna, is typically well over a mile.

Its sister, the

SqwakBox, also produces 50 milliwatts of FM-modulated RF on 2-meters,

but its assembled on a slightly larger board, measuring 0.9 X 2.4

inches, and includes a voice record/playback chip with 60-second

recording capacity, and an integrated electret microphone to record a

message.

The

SqwakBox makes use of a PIC 16F84 micro for supervision, ISD2560 for

voice record/playback and an ICS525 PLL CPU clock generator chip.

Messages can be recorded by pressing a "record" button and speaking

into the integrated microphone. Its mostly intended for recreational

2-meter transmitter hunts.

The first step regarding assembling

these transmitters is to find an enclosure. Just about any electronics

enclosure would work. We wanted something that was small, lightweight,

and had a good surface to mount an antenna, and on/off switch. Checking

several options online, we decided on plastic enclosures with removable

tops, and room enough to mount the necessary 9-volt battery. Believe it

or not, it was less expensive to purchase these from their manufacturer

in Poland and ship them, than from the US distributor. The antennas we

chose are Nagano 2 meter HT "flexi" ducks. We added an on/off switch so

we didn't have to worry about disconnecting the battery when not in

use. Besides the enclosure and switch, the only other parts required to

assemble them were BNC chassis connectors for the antenna, some wire,

and 9-volt battery connectors.

For more info on the parts used in

this project, please visit:

Doppler DF Instruments

Electronics Enclosures

Restoring

the EL-Key

The

EL-Key is an important paddle in the history of amateur radio.

This single lever design was the first commercially manufactured paddle

offered to ham radio operators. They were made by R.E. Poucel (W2AYJ)

and Sid Shore (K2FC) doing business as "Poucel Electronics," a division

of Shore Mfg. Co., of Long Island NY, starting in 1959. Today they are

very scarce, and sought after by collectors.

While

searching for an EL-Key, we were looking for two important qualities -

a key which had all the components intact, and one which still had the

all-important name plate attached and undamaged. Everything else could

be restored.

The

first step in any restoration process is to

decide what needs to be done. This one was in obvious need of new paint

on the base, and the lever, upon initial inspection, didn't function as

it should have - It was frozen and had no springing action. To begin,

we

would need to remove all of the components from the base. Before

disassmbling anything, however, its a good idea to take pictures and to

draw diagrams of how everything is attached and wired.

The

main carriage comes off with just two bolts, allowing removal of the

swing arm assembly. A flat head screw driver is the only tool that is

required. The rest of the components are simple upright posts which act

as electrical contacts, spring holders, or stops. They all remove with

a single machine screw, threaded from the underside of the base.

Once

everything is removed, the base can be sanded and prepped for paint. We

used two different grits of sandpaper with a sanding block. The first

was 220, followed by 320, making sure to smooth out all the chips and

scratches. Then the base was cleaned with solvent and set aside for

painting. Our base was painted by our good friends at Moody's Collision

Center, in Scarborough, Maine. We chose Volvo paint code 019, which is

a solid black, closely resembling the original color.

The

rest

of the components were cleaned and polished, and much of the stripped

or worn hardware was disgarded and replaced. For the plastic paddles,

which were yellowed and scratched, we used Mothers Plastic Polish,

which removed almost all of the surface scratches and yellowing. Then

we

gave it a finishing coat of Zymol Concours Glaze. The metal components

were polished with mag and aluminum polish, then finished with Zymol.

We discovered that the problem with the side-to-side motion of the

lever assembly was a missing spring, and a badly bent center bolt.

With these replaced, the left side motion was restored.

With

all the components repaired and polished, and the base back from the

body shop, we began the reassembly process. Consulting our photographs

and wiring diagram, the process went smoothly. The wiring was straight

forward, but required a few connectors to be soldered to the wires, and

to each other, to match the original layout. On removal, some of these

just fell apart. The finishing touch was to reapply the EL-Key

nameplate, which was done with a two-part epoxy called J-B Weld.

So

there you have it - a fully restored 1959 EL-Key, ready to get back on

the air and make some QSO's!

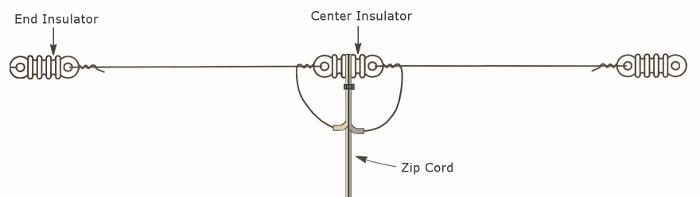

Constructing

a 20 meter Dipole

What

is a Dipole Antenna?

We

chose to build dipole antennas for our field activity because they are

cheap to produce, very efficient, and easy to construct. But why are

they effective? Let’s take a closer look, as we examine just what a

dipole is...

A

dipole

is a balanced antenna. It consists of

two haves, which extend in opposite directions from a feed point at the

center. It is commonly called a “half-wave dipole” since the entire

antenna is ½- wavelength long at the desired operating frequency.

Why

do we start here? In its simplest form the dipole is very dependable.

It’s easy to construct, tune, and to install, but it is also the

building block for other, more complex antennas. Once you understand

the techniques involved in making the dipole, they can be applied to

any type of wire antenna including the “Full Sloper,” “Inverted V,”

“End-Fed Zepp,” “Folded,” and “Trap” varieties of the dipole.

For

our example, we will construct a simple, center-fed dipole for the

20 meter band. To do this we need the following materials:

1 spool of 14 gage copper-strand wire (for the radiated elements)

1 spool of lamp cord, or “zip line” (for the center feed line)

2 commercially available plastic end insulators

1 Center insulator

Nylon Rope |

The

following tools are also required:

Scissors

Wire Cutters

Soldering iron

Wire Strippers

Electrical Tape

Zip tie |

The

first step is to determine the total length of the antenna. We do this

(for frequencies up to 30 MHz), by using the following formula:

Length

of half-wave antenna in feet

= 492 X 0.95

/ f(MHz) =

468 / f(MHz)

A

half-wave antenna for 14.200 MHz

= 468 / 14.200 = 32.96 ft.

Divide this number

by 2 to get the length of each leg, and we have 16.48 ft. Keep in mind

that it’s a good idea to cut the wire a few inches longer than the

calculated length, since some of the resonating area of the wire will

be lost when it is tied back onto the insulators.

After

this

is done, cut a length of feed line. We used what is commonly called

“zip cord,” which is simply the electrical cord used on lamps or other

appliances. Cut a length of about twenty-five feet, and strip the ends

(about three inches on the end that will connect to the center

insulator). Although there are many ways to connect the feed line, we

chose to use a commercially available insulator made of plastic. This

could also be made from PVC tubing, wood, or even a scrap of Lexan. The

commercially made insulator has a fat round center with grooves in it,

and holes drilled on the ends. Secure the feed line to it by

wrapping it tightly around the center grooves and securing it with a

plastic tie, leaving enough of the stripped wire to loop around and

eventually connect to each leg.

Similarly,

attach the antenna legs to the center insulator, by looping each end

through the holes, and wrapping it around itself several times. Then,

connect one side of the stripped feed line to a leg of the

stranded antenna wire, and repeat with the other side. Do a good job of

soldering the antenna and feed line connections. When you’re finished

soldering, and it cools, wrap the connections with electrical tape for

water-proofing.

After

this

is completed, attach the end

insulators in a similar fashion, looping each end through a hole on the

insulator, but don’t solder just yet.

The

antenna is nearly

complete. Raise it to a working height, and check the SWR at several

frequencies across the band. Most dipoles require a little pruning to

raise the resonance the desired frequency. Remember to trim each end

equally. When you’re satisfied with the SWR, lower the antenna and

secure each end with solder, and when it cools, tape the connections to

waterproof.

There’s

a

few things to consider about how to

connect the feed line to your radio. We simply soldered a PL 259

connector to the zip cord and plugged it in directly to the radio, but

it’s probably a good idea to use a balun if the dipole is fed with

coax. The disadvantages of coax are increased RF loss and low working

voltage, but sometimes it can’t be helped. The most efficient way to

feed a dipole is with 450 ohm ladder line. Ladder line has extremely

low loss, and although zip cord has a little more, they both can stand

very high voltages (SWR).

Now

you’ve

done it. You made a dipole. Go tell the world!

One

advantage of the dipole is that its takes up little space, when

compared to a yagi, and doesn’t require a tower to get it up.

Simply put it in a tree, or if none is available, set up a mast or two,

and you’re on the air. They can be made of almost any wire or tubing,

and can be set up in an infinite number of configurations. The dipole

is popular because of its simplicity, and the fact that it can be

erected quickly in emergency situations. They are the choice of EmComm

operators and dx’ers alike. During our field operation on September

18th, we put up three dipoles for the 20, 40, and 80 meter bands in

just 15 minutes, and made nearly fifty contacts in just a few hours.

|